The outside of the tank is finished–here are a couple of pics of it. As mentioned, it has two layers, which need to be put on within a day of each other, so they bond–fortunately the weather has been cool and damp, which is ideal for the curing of concrete.

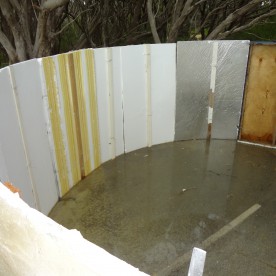

I’ve also shown a couple of pics of the inside form work, for the record. These will now come off and the inside layer will be put on–only one layer so it should go quickly.

Then everything will cure for a week or so, depending on the weather; then it will be filled half full from the bore water and will continue to cure for a month.

While that happens the house site will be laid out (including establishing true north, which promises to be interesting!) and preparations for the footings made. Moving on!