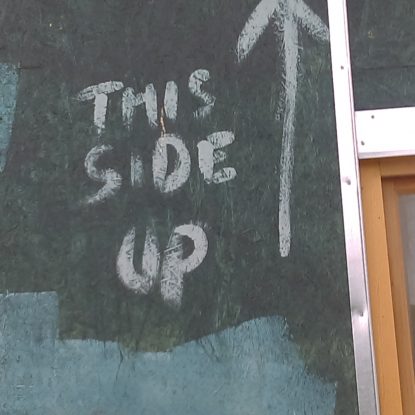

The boys have been gyprocking this week–along with other things that you can’t really see, like putting in bathroom plumbing, flashing along the footings, and so on.

Also, the timber for the Vastu fence has turned up–it is lovely wood, native Callitris from a plantation mill in Queensland–Steven at the Robe Hardware sourced it and had it shipped down through Melbourne–and charged us only a bit more delivered than local imported cypress.

(The cypress comes from Biscuit Flat–in the early days they cleared the native vegetation there and soon discovered that there was no shelter for stock from the winter gales–so they planted these fast-growing trees, which you can see everywhere in belts and around the homesteads. They are finally reaching the end of their natural lives, and are falling over, so are being milled and sold locally as garden timber. But I wanted the native timber, if I could get it as plantation timber, because it has much better qualities. Just some irrelevant information, as I am interested in these matters of environmental history. . .)

Callitris grows naturally in SA–we have four trees growing down at the shed–and was used in the early houses because it is highly resistant to insect and rot–a brilliant construction timber. There is 150 metres of it here, for the Vastu square of 18 metres per side, with two railings, and a bit left over. The Davidsons are kindly donating some posts they have left over from their block work on Evans Cave Rd. We are setting up for a working weekend to put the whole thing in at one go–we have a few young people targeted–as the last thing, once everything else is done.

And just for good measure as we were driving out, about half way down our drive, an echidna was getting along. By the time I got out of the car to take the photo she/he had moved into defensive mode, spines out–which is how they have survived for 200 million years, I suppose. With the platypus they are the last survivors of the Order Monotremata (the common ancestor of Monotremes and Mammals was around in Mesozoic times, with the dinosaurs). Really we were very happy to see her/him and I just wanted to say, welcome, we’re honoured.